Fermentation-derived fats and oils: from Engineering Strategies to Emerging Technology

single cell oil and fat production

Keywords:

SCO, Fermented fats, Microbial oils, Precision fermentation, Sustainable lipids, Waste-to-oil bioconversionAbstract

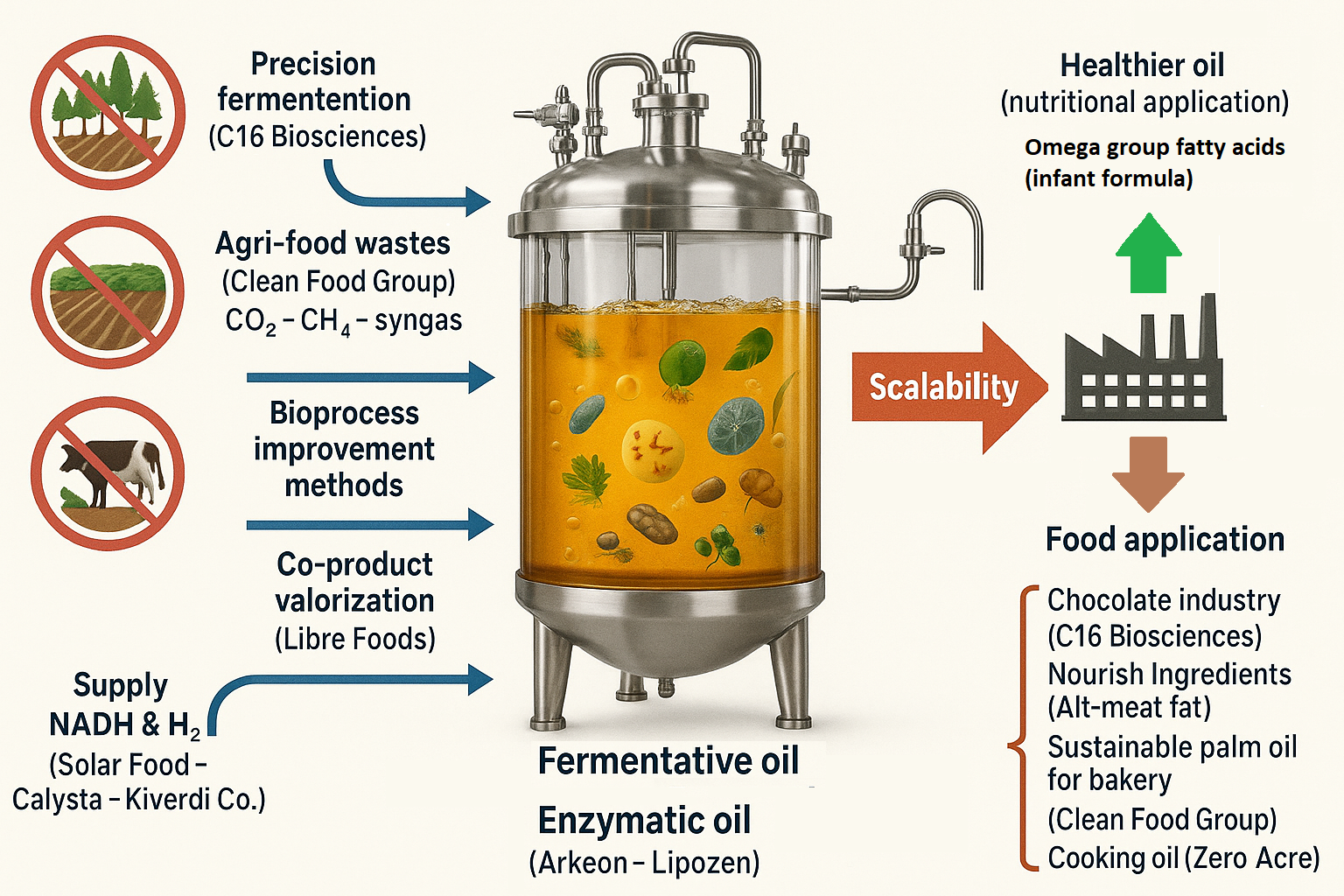

Developing novel fat and oil ingredients through fermentation is an emerging field with great potential to address sustainability, health, and functionality challenges in the food industry. This review highlights new strategies such as precision fermentation for specialty fats, waste-to-oil bioconversion, hybrid blends with plant-based fats, and scalable bioreactor designs. Despite promising applications in food sectors, there are still challenges like high production costs, and scalability barriers. Advances in feedstock diversification, co-product valorization, and innovative fermentation systems are key to overcoming these hurdles. A few companies demonstrate progress, while economic and technological innovations are expected to enable mainstream adoption in the coming decade.

Downloads

References

1. Adrio JL. Oleaginous yeasts: Promising platforms for the production of oleochemicals and biofuels. Biotechnol Bioeng. 2017;114(9):1915-20.

2. Adamczyk PA, Jiang T, Jetty K, Ganesan V, Liu D. Recent developments of oleaginous yeasts toward sustainable biomanufacturing. Current Opinion in Biotechnology. 2025;93:103297.

3. Muro E, Atilla-Gokcumen GE, Eggert US. Lipids in cell biology: how can we understand them better? Molecular biology of the cell. 2014;25(12):1819-23.

4. Mahajan D, Sengupta S, Sen S. Strategies to improve microbial lipid production: Optimization techniques. Biocatalysis and Agricultural Biotechnology. 2019;22.

5. Mata TM, Martins AA, Caetano NS. Microalgae for biodiesel production and other applications: A review. Renewable and Sustainable Energy Reviews. 2010;14(1):217-32.

6. Makepa DC, Chihobo CH, Musademba D. Techno-economic analysis and environmental impact assessment of biodiesel production from bio-oil derived from microwave-assisted pyrolysis of pine sawdust. Heliyon. 2023;9(11):e22261.

7. Ochsenreither K, Glück C, Stressler T, Fischer L, Syldatk C. Production Strategies and Applications of Microbial Single Cell Oils. Frontiers in Microbiology. 2016;Volume 7 - 2016.

8. Nicaud J-M, editor Microorganisms as sources of oils2013.

9. Ratledge C. Fatty acid biosynthesis in microorganisms being used for Single Cell Oil production. Biochimie. 2004;86(11):807-15.

10. Nazir Y, Halim H, Prabhakaran P, Hamid AA, Song Y. Chapter 16 - Microalgae single cell oil. In: Jacob-Lopes E, Maroneze MM, Queiroz MI, Zepka LQ, editors. Handbook of Microalgae-Based Processes and Products: Academic Press; 2020. p. 419-44.

11. Yousuf A, Sannino F, Addorisio V, Pirozzi D. Microbial conversion of olive oil mill wastewaters into lipids suitable for biodiesel production. Journal of agricultural and food chemistry. 2010;58(15):8630-5.

12. Khot M, Raut G, Ghosh D, Alarcón-Vivero M, Contreras D, Ravikumar A. Lipid recovery from oleaginous yeasts: Perspectives and challenges for industrial applications. Fuel. 2020;259:116292.

13. Shi S, Zhao H. Metabolic Engineering of Oleaginous Yeasts for Production of Fuels and Chemicals. Front Microbiol. 2017;8:2185.

14. Koutinas AA, Chatzifragkou A, Kopsahelis N, Papanikolaou S, Kookos IK. Design and techno-economic evaluation of microbial oil production as a renewable resource for biodiesel and oleochemical production. Fuel. 2014;116:566-77.

15. Sitepu IR, Garay LA, Sestric R, Levin D, Block DE, German JB, et al. Oleaginous yeasts for biodiesel: current and future trends in biology and production. Biotechnol Adv. 2014;32(7):1336-60.

16. Papanikolaou S, Aggelis G. Lipids of oleaginous yeasts. Part II: Technology and potential applications. European Journal of Lipid Science and Technology. 2011;113(8):1052-73.

17. Blazeck J, Hill A, Liu L, Knight R, Miller J, Pan A, et al. Harnessing Yarrowia lipolytica lipogenesis to create a platform for lipid and biofuel production. Nat Commun. 2014;5:3131.

18. Beopoulos A, Cescut J, Haddouche R, Uribelarrea JL, Molina-Jouve C, Nicaud JM. Yarrowia lipolytica as a model for bio-oil production. Prog Lipid Res. 2009;48(6):375-87.

19. Huang C, Chen XF, Xiong L, Chen XD, Ma LL, Chen Y. Single cell oil production from low-cost substrates: the possibility and potential of its industrialization. Biotechnol Adv. 2013;31(2):129-39.

20. Shi TQ, Huang H, Kerkhoven EJ, Ji XJ. Advancing metabolic engineering of Yarrowia lipolytica using the CRISPR/Cas system. Appl Microbiol Biotechnol. 2018;102(22):9541-8.

21. Qiao K, Wasylenko TM, Zhou K, Xu P, Stephanopoulos G. Lipid production in Yarrowia lipolytica is maximized by engineering cytosolic redox metabolism. Nature Biotechnology. 2017;35(2):173-7.

22. Caporusso A, Giuliano, A., Liuzzi, F., & De Bari, I. Techno-economic Analysis of a Lignocellulosic Biorefinery Producing Microbial Oils by Oleaginous Yeasts. Chemical Engineering Transactions. 2022;92:637-42.

23. Gunstone FD. F. D. Gunstone. 1st

ed: Woodhead; 2006.

24. Shahidi F, Zhong Y. Lipid oxidation and improving the oxidative stability. Chem Soc Rev. 2010;39(11):4067-79.

25. Sun H, Gao Z, Zhang L, Wang X, Gao M, Wang Q. A comprehensive review on microbial lipid production from wastes: research updates and tendencies. Environmental Science and Pollution Research. 2023;30(33):79654-75.

26. Tomás-Pejó E, Morales-Palomo S, González-Fernández C. Microbial lipids from organic wastes: Outlook and challenges. Bioresource Technology. 2021;323:124612.

27. Kobalter S, Wriessnegger T, Pichler H. Engineering yeast for tailored fatty acid profiles. Applied Microbiology and Biotechnology. 2025;109(1):101.

28. Elsamadony M, Mostafa A, Fujii M, Tawfik A, Pant D. Advances towards understanding long chain fatty acids-induced inhibition and overcoming strategies for efficient anaerobic digestion process. Water Research. 2021;190:116732.

29. Liu Y, Xi Y, Li Q, Dzakpasu M, Chen R, Li YY. Biokinetic and microbial insights into regulatory mechanisms of long-chain fatty acid degradation during food waste-lipid co-digestion within anaerobic membrane bioreactor. Bioresour Technol. 2024;408:131223.

30. ADM. ADM Further Expands Microbial Science and Technology Innovation Capabilities with Investment in Precision Fermentation Leader Acies Bio 2021 [Available from: https://www.adm.com/en-us/news/news-releases/2021/10/adm-further-expands-microbial-science-and-technology-innovation-capabilities-with-investment-in-precision-fermentation-leader-acies-bio/?utm_source=chatgpt.com.

31. Robles-Iglesias R, Naveira-Pazos C, Fernández-Blanco C, Veiga MC, Kennes C. Factors affecting the optimisation and scale-up of lipid accumulation in oleaginous yeasts for sustainable biofuels production. Renewable and Sustainable Energy Reviews. 2023;171:113043.

32. FDA. Generally Recognized as Safe (GRAS). 2023.

33. PWMarketResearch. Oil Market research. 2025.

34. Albertsen L, Wiedmann K-P, Schmidt S. The impact of innovation-related perception on consumer acceptance of food innovations – Development of an integrated framework of the consumer acceptance process. Food Quality and Preference. 2020;84:103958.

35. Aondoakaa IP, Akoh CC. Microbial and insect oils: A sustainable approach to functional lipid. Journal of the American Oil Chemists' Society. 2025;102(1):5-33.

36. Banovic M, Grunert KG. Consumer acceptance of precision fermentation technology: A cross-cultural study. Innovative Food Science & Emerging Technologies. 2023;88:103435.

37. Bryant C, Barnett J. Consumer Acceptance of Cultured Meat: An Updated Review (2018–2020). Applied Sciences. 2020;10(15):5201.

38. Vemparala G, Chiliveru A, Begum S, Amri MBFA, Anupoju GR. Analyzing and optimizing the lipids production potential of the oleaginous yeast Candida neerlandica from synthetic carbon sources and real wastes. Next Research. 2025;2(2).

39. Zhu J, Gu Y, Yan Y, Ma J, Sun X, Xu P. Knocking out central metabolism genes to identify new targets and alternating substrates to improve lipid synthesis in Y. lipolytica. Front Bioeng Biotechnol. 2023;11:1098116.

40. Zhang H, Cui Q, Song X. Research advances on arachidonic acid production by fermentation and genetic modification of Mortierella alpina. World Journal of Microbiology and Biotechnology. 2021;37(1):4.

41. Ren Z, Armenta RE, Brooks MS-L. Arachidonic acid production by Mortierella alpina MA2-2: Optimization of combined nitrogen sources in the culture medium using mixture design. Bioresource Technology Reports. 2025;29:102049.

42. Wang Y, Tang X, Wang S, Zhang H, Chen YQ, Chen H, et al. Application of the cbh1 promoter in Mortierella alpina and optimization of induction conditions. Letters in Applied Microbiology. 2020;71(2):164-70.

43. Watanabe K, Perez CMT, Kitahori T, Hata K, Aoi M, Takahashi H, et al. Improvement of fatty acid productivity of thraustochytrid, Aurantiochytrium sp. by genome editing. Journal of Bioscience and Bioengineering. 2021;131(4):373-80.

44. Zhang L, Lee JTE, Ok YS, Dai Y, Tong YW. Enhancing microbial lipids yield for biodiesel production by oleaginous yeast Lipomyces starkeyi fermentation: A review. Bioresource Technology. 2022;344:126294.

45. Takaku H, Matsuzawa T, Yaoi K, Yamazaki H. Lipid metabolism of the oleaginous yeast Lipomyces starkeyi. Applied Microbiology and Biotechnology. 2020;104:6141 - 8.

46. Jacob&Mathew. Recent advances in using Lipomyces starkeyi for the Production of Single-Cell Oil. Journal of Pure and applied microbiology. 2023;17(2):693-704.

47. McNeil BA, Stuart DT. Lipomyces starkeyi: an emerging cell factory for production of lipids, oleochemicals and biotechnology applications. World Journal of Microbiology and Biotechnology. 2018;34.

48. Sha Y, Zhou L, Wang Z, Ding Y, Lu M, Xu Z, et al. Adaptive laboratory evolution boosts Yarrowia lipolytica tolerance to vanillic acid. Journal of Biotechnology. 2023;367:42-52.

49. Chen C, Li Y-W, Chen X-Y, Wang Y-T, Ye C, Shi T-Q. Application of adaptive laboratory evolution for Yarrowia lipolytica: A comprehensive review. Bioresource Technology. 2024;391:129893.

50. Zhu LY, Zong MH, Wu H. Efficient lipid production with Trichosporonfermentans and its use for biodiesel preparation. Bioresource Technology. 2008;99(16):7881-5.

51. Back A, Rossignol T, Krier F, Nicaud JM, Dhulster P. High-throughput fermentation screening for the yeast Yarrowia lipolytica with real-time monitoring of biomass and lipid production. Microb Cell Fact. 2016;15(1):147.

52. Park BG, Kim J, Kim E-J, Kim Y, Kim J, Kim JY, et al. Application of Random Mutagenesis and Synthetic FadR Promoter for de novo Production of ω-Hydroxy Fatty Acid in Yarrowia lipolytica. Frontiers in Bioengineering and Biotechnology. 2021;Volume 9 - 2021.

53. Tapia V E, Anschau A, Coradini ALV, T Franco T, Deckmann AC. Optimization of lipid production by the oleaginous yeast Lipomyces starkeyi by random mutagenesis coupled to cerulenin screening. AMB Express. 2012;2(1):64.

54. Arora N, Patel A, Mehtani J, Pruthi PA, Pruthi V, Poluri KM. Co-culturing of oleaginous microalgae and yeast: paradigm shift towards enhanced lipid productivity. Environ Sci Pollut Res Int. 2019;26(17):16952-73.

55. Ray A, Nayak M, Ghosh A. A review on co-culturing of microalgae: A greener strategy towards sustainable biofuels production. Science of The Total Environment. 2022;802:149765.

56. Zhang L, Tsui T-H, Tong YW, Liu R, Smoliński A. Process Engineering Technologies for Optimization and Enhancement of the Microbial Fermentation for Lipid Production. Microbial Lipids and Biodiesel Technologies: Springer; 2025. p. 205-22.

57. Bioscience C. C16 Biosciences Launches Palmless™ Bio-Manufactured Alternative to Palm Oil, Reveals Beauty as First-To-Market Product In Early 2023 2023 [Available from: https://www.c16bio.com/press-awards/c16-biosciences-launches-palmless-tm-bio-manufactured-alternative-to-palm-oil-reveals-beauty-as-first-to-market-product-in-early-2023.

58. Ingredients N. Fonterra and Nourish Ingredients join forces to develop innovative new products 2024 [Available from: https://www.fonterra.com/nz/en/our-stories/articles/fonterra-and-nourish-ingredients-join-forces-to-develop-innovative-new-products.html#:~:text=Nutrition-,Fonterra%20and%20Nourish%20Ingredients%20join%20forces%20to%20develop%20innovative%20new,delicious%20taste%20of%20traditional%20dairy.

59. Perfectday. Expanding Our Portfolio: Announcing Flora-Made Fats 2019 [

60. Dias B, Fernandes H, Lopes M, Belo I. Yarrowia lipolytica produces lipid-rich biomass in medium mimicking lignocellulosic biomass hydrolysate. Applied Microbiology and Biotechnology. 2023;107(12):3925-37.

61. Gao R, Li Z, Zhou X, Cheng S, Zheng L. Oleaginous yeast Yarrowia lipolytica culture with synthetic and food waste-derived volatile fatty acids for lipid production. Biotechnology for Biofuels. 2017;10(1):247.

62. Pereira AS, Lopes M, Duarte MS, Alves MM, Belo I. Integrated bioprocess of microbial lipids production in Yarrowia lipolytica using food-waste derived volatile fatty acids. Renewable Energy. 2023;202:1470-8.

63. Ravi Gedela VVD, Kannan Pakshirajan Square. Valorization of Dairy Wastewater for the Production of Lipids, Carotenoids, and β-Carotene in Rhodotorula mucilaginosa. 2024.

64. Gedela R, Sharma S, Prabhu AA, Pakshirajan K, Veeranki VD. Elevated production of lipids and carotenoids from Rhodotorula mucilaginosa using raw dairy wastewater as crude renewable substrate: a waste to wealth transformation approach. Chemical Papers. 2025;79(7):4403-18.

65. Rafiq S, Bhat MI, Sofi SA, Muzzafar K, Majid D, Dar BN, et al. Bioconversion of agri-food waste and by-products into microbial lipids: Mechanism, cultivation strategies and potential in food applications. Trends in Food Science & Technology. 2023;139:104118.

66. Zhang L, Loh K-C, Kuroki A, Dai Y, Tong YW. Microbial biodiesel production from industrial organic wastes by oleaginous microorganisms: Current status and prospects. Journal of Hazardous Materials. 2021;402:123543.

67. Dar RA, Tsui T-H, Zhang L, Tong YW, Sharon S, Shoseyov O, et al. Fermentation of organic wastes through oleaginous microorganisms for lipid production - Challenges and opportunities. Renewable and Sustainable Energy Reviews. 2024;195:114328.

68. Al Shehhi A, Souissi Y, Nair AS, Usmani Z, Sharma M, Sivakumar N. Microbial lipid-based biodiesel production using wastewater: opportunities and challenges. Bioresour Bioprocess. 2025;12(1):70.

69. Wiebe MG. Myco-protein from Fusarium venenatum: a well-established product for human consumption. Appl Microbiol Biotechnol. 2002;58(4):421-7.

70. Pawar PP, Odaneth AA, Vadgama RN, Lali AM. Simultaneous lipid biosynthesis and recovery for oleaginous yeast Yarrowia lipolytica. Biotechnology for Biofuels. 2019;12(1):237.

71. Robles-Iglesias R, Veiga MC, Kennes C. Sequential bioconversion of C(1)-gases (CO, CO(2), syngas) into lipids, through the carboxylic acid platform, with Clostridium aceticum and Rhodosporidium toruloides. J Environ Manage. 2023;347:119097.

72. consortium Bi. 2023 [Available from: https://biconsortium.eu/member/kiverdi#:~:text=Kiverdi%20technology%20uses%20all%2Dnatural,for%20consumer%20and%20industrial%20applications.

73. PhaseBio DBa. Chemicals from thin air: gas fermentation and the future of bio-manufacturing 2020 [

74. Rabaey K, Rozendal RA. Microbial electrosynthesis — revisiting the electrical route for microbial production. Nature Reviews Microbiology. 2010;8(10):706-16.

75. Foods S. Solar Foods confirms 100-fold scaleup of Solein production at Factory 01 2024 [Available from: https://solarfoods.com/solar-foods-confirms-successful-100-fold-industrial-scaling-of-soleins-production-technology/.

76. SolarFoods. Company technology and sustainability roadmap 2023 [Available from: https://solarfoods.com.

77. de Mello AFM, de Souza Vandenberghe LP, Herrmann LW, Letti LAJ, Burgos WJM, Scapini T, et al. Strategies and engineering aspects on the scale-up of bioreactors for different bioprocesses. Systems Microbiology and Biomanufacturing. 2024;4(2):365-85.

78. Hughes C. Achieving scalable and sustainable precision fermentation using Process Analytical Technology 2024 [Available from: https://www.pharmasalmanac.com/articles/achieving-scalable-and-sustainable-precision-fermentation-using-process-analytical-technology.

79. Sung MG, Lee B, Kim CW, Nam K, Chang YK. Enhancement of lipid productivity by adopting multi-stage continuous cultivation strategy in Nannochloropsis gaditana. Bioresource technology. 2017;229:20-5.

80. Li X, Xu H, Wu Q. Large-scale biodiesel production from microalga Chlorella protothecoides through heterotrophic cultivation in bioreactors. Biotechnology and Bioengineering. 2007;98(4):764-71.

81. Sung M-G, Lee B, Kim CW, Nam K, Chang YK. Enhancement of lipid productivity by adopting multi-stage continuous cultivation strategy in Nannochloropsis gaditana. Bioresource Technology. 2017;229:20-5.

82. Sirirak K PS, Suanjit S, Jaritkhuan S. . Effectiveness of various bioreactors for thraustochytrid culture and production (Aurantiochytruim limacinum BUCHAXM 122) PeerJ. 2021;9:e11405.

83. Li X, Xu H, Wu Q. Large‐scale biodiesel production from microalga Chlorella protothecoides through heterotrophic cultivation in bioreactors. Biotechnology and Bioengineering. 2007;98.

84. Du Y-H, Wang M-Y, Yang L-H, Tong L-L, Guo D-S, Ji X-J. Optimization and Scale-Up of Fermentation Processes Driven by Models. Bioengineering. 2022;9(9):473.

85. Felix Garcia-Ochoa EG. Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnology Advances. 2009.

86. Bergstrom JD. The lipogenic enzyme acetoacetyl-CoA synthetase and ketone body utilization for denovo lipid synthesis, a review. Journal of Lipid Research. 2023;64(8):100407.

87. Sharma N, Ahlawat YK, Stalin N, Mehmood S, Morya S, Malik A, et al. Microbial Enzymes in Industrial Biotechnology: Sources, Production, and Significant Applications of Lipases. J Ind Microbiol Biotechnol. 2024;52.

88. Usui H, Kojima H, Domi Y, Sakaguchi H. Regeneration of Nicotinamide Adenine Dinucleotide Phosphate by a Chlorophyll a-Coated TiO2 Film Electrode. ACS Applied Bio Materials. 2021;4(8):5975-80.

89. Wei Lan MW, Huicong Dai, Qihua Yang. Recent progress in photocatalytic NAD(P)H regeneration for photocatalytic-enzymatic-coupling system. Front Chem Sci Eng. 2024;18(4):37-${article.jieShuYe}.

90. Greenchemistryforsustainability. NovaLipid™ and Lipozyme [Available from: https://chemistryforsustainability.org/safer-alternatives/novalipidtm-and-lipozymer?utm_source=chatgpt.com.

91. steakholderfoods. Steakholder Foods Launches Innovative Ink to 3D Print Beef Steaks 2023 [Available from: https://www.steakholderfoods.com/blog/steakholder-foods-launches-innovative-ink-to-3d-print-beef-steaks?utm_source=chatgpt.com.

92. Lucas Eastham AB, Adam Leman. Driving Down Costs 2025 [Available from: https://gfi.org/wp-content/uploads/2025/06/Driving-down-costs-of-fermentation-derived-ingredients.pdf?utm_source=chatgpt.com.

93. Argota J. Palm Oil Price Guide: Global Market Analysis & Investment Insights 2025 [Available from: https://greaseconnections.com/palm-oil-price-guide-2025/?utm_source=chatgpt.com.

94. BMI. Palm Oil Price Forecast: Revised 2025 Outlook As Production Challenges In Malaysia And Indonesia Tighten Supply Forecast 2025 [Available from: https://www.fitchsolutions.com/bmi/agribusiness/palm-oil-price-forecast-revised-2025-outlook-production-challenges-malaysia-and-indonesia-tighten-supply-forecast-27-03-2025?utm_source=chatgpt.com.

95. Ge F, Chen G, Qian M, Xu C, Liu J, Cao J, et al. Artificial Intelligence Aided Lipase Production and Engineering for Enzymatic Performance Improvement. Journal of Agricultural and Food Chemistry. 2023;71(41):14911-30.

96. Imamoglu E. Artificial Intelligence and/or Machine Learning Algorithms in Microalgae Bioprocesses. Bioengineering. 2024;11(11):1143.

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 2025 Zahra Montazer, Riffat Munir (Author); Khosravi

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.